OLD MACHINE UPGRADES

If you have an older Autopac machine that is no longer performing at its best, we have two types of machine upgrades available to meet your needs:

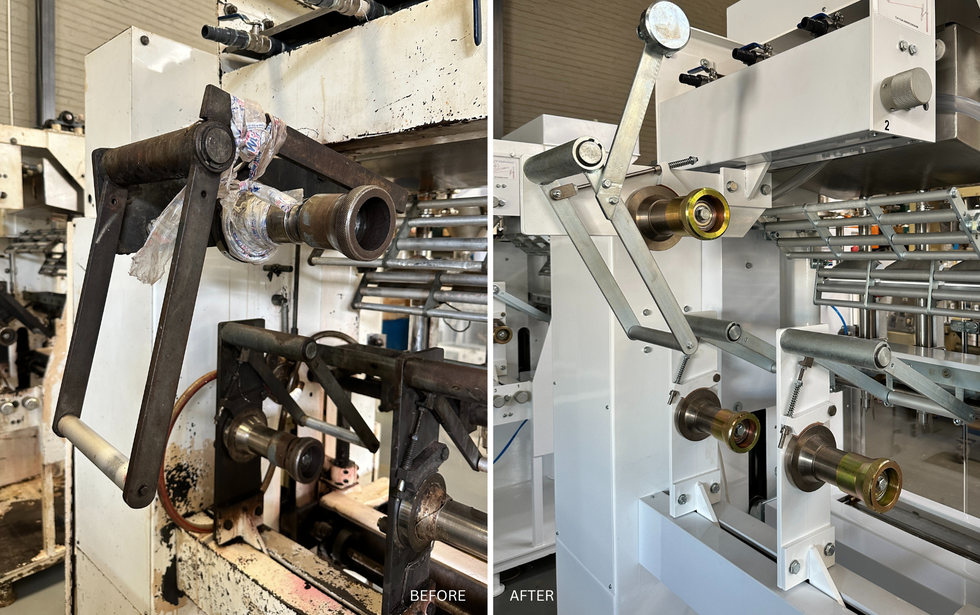

Before and after a full machine rebuild.

1. THE BASICS: A MECHANICAL UPGRADE

Our basic upgrade option focuses on addressing the essentials. We will service your machine by repairing or replacing any worn, damaged or missing wearable and mechanical parts. We do not upgrade the cosmetic appearance, but rather focus on giving your machine the functional upgrade it needs to get back up and running again while keeping your finances in mind.

2. A FULL MACHINE REBUILD

When you choose our full machine rebuild option, you can expect a comprehensive upgrade that will transform your machine to the standard of a new one, complete with both cosmetic and functional upgrades.

Our range of services under the full machine rebuild option includes:

- Full machine assessment.

- Full strip, cleaning and assessment of all parts.

- Repair and repainting of all painted parts.

- Repair and re-plating of all zinc plated, nickel, and anodized parts.

- Replacement of damaged or worn parts with new parts.

- New electrical wiring.

- Assembly, testing, and commissioning.

LET'S REBUILD YOUR MACHINE

Whether you opt for the basics or a full machine rebuild, our goal is to improve your productivity and extend the life of your Autopac machine. Contact us at sales@autopac.co.za or give us a call at +27 11 792 1835 to discuss your machine upgrade options. Our experienced team is ready to assist you in finding the best solution to meet your requirements.

If you'd like to see how a full machine rebuild can breathe new life into our machines, have a look below at some of the before and after photos of three Ice Lolly Machines that we recently rebuilt for a customer.

MODIFICATIONS / ADDITIONS

At Autopac we understand that as your business grows, you may need to modify and enhance your packaging machinery to meet your evolving needs. Our dedicated team is here to support you in exploring the available options and finding the ideal solution to optimize your packaging processes.

Since each machine we create is tailored to your specific requirements, we will first assess your machine to determine the most cost-effective approach to help you move forward. Here are a few examples of how you might require us to assist you:

- You need to pack a new bag width.

- You'd like to pack a different product weight.

- You want to use a different packaging material.

- You'd like to add traceability.

- Ancillary equipment is needed.

To discuss any modifications or additional equipment you may require and to explore the available options for your production line, please feel free to contact us at sales@autopac.co.za or give us a call at +27 11 792 1835. Our dedicated team is ready to assist you with expert guidance, to find the perfect solution for you.